-

01 May 2024Mining and MetalsGeochemistry Part II: Predicting metal leaching and acid rock drainage (ML/ARD) chemistry

-

Todd McCracken, P.Geo

Department Manager, Mining and Geology

-

-

15 Apr 2024Mining and MetalsGeochemistry Part I: What is metal leaching and acid rock drainage (ML/ARD), and how does it occur?

-

Todd McCracken, P.Geo

Department Manager, Mining and Geology

-

-

06 Dec 2023Power and RenewablesDeveloping a reliable mining decarbonization plan

-

Dave Olsthoorn, P.Eng., M.A.Sc.

Engineer, Energy and Air Quality

-

-

03 May 2023Mining and MetalsProperly preparing a strategic plan to pump mine tailings

-

Guylaine St-Jean, P.Eng.

Senior Engineer, Industrial and Hydro

-

-

28 Nov 2022Power and RenewablesReverse osmosis: A reliable technology

-

-

07 Nov 2022Power and RenewablesMulti-tiered bracing systems design

-

-

21 Apr 2022Mining and MetalsChute design: What you need to understand and the relevance of the DEM tool

-

-

13 Dec 2021Mining and MetalsStress-strain analysis of tailings facilities subject to dynamic loads

-

-

Mining and MetalsOptimized design management of mining structures and waste rock piles

Mine Tailings and Waste Management

Many of the everyday products we enjoy contain minerals, and the demand for these raw materials continues to grow. However, mineral extraction generates tailings and waste that mining operators must manage responsibly to minimize the environmental impact of their operations while ensuring the safety of neighbouring communities.

How can you successfully fulfill your regulatory and social obligations without eating away at your profit margins? It’s important to be aware of the real costs associated with your mine waste and tailings, and to ensure their rigorous planning and management.

Mine Tailings and Waste Management

-

Your challenges

-

Conducting operations in a more sustainable and economical way

Understanding the full cost of managing your tailings can help you identify sources of considerable savings and profitability. Your goal is to find technical solutions that are both practical and economical, so you can dispose of your tailings, whether solid or liquid, while respecting regulations related to your area of activity. There are various factors to consider when choosing solutions, such as the distance tailings must travel before disposing of them.

Your challenges:

- Identify and manage long-term tailings risks

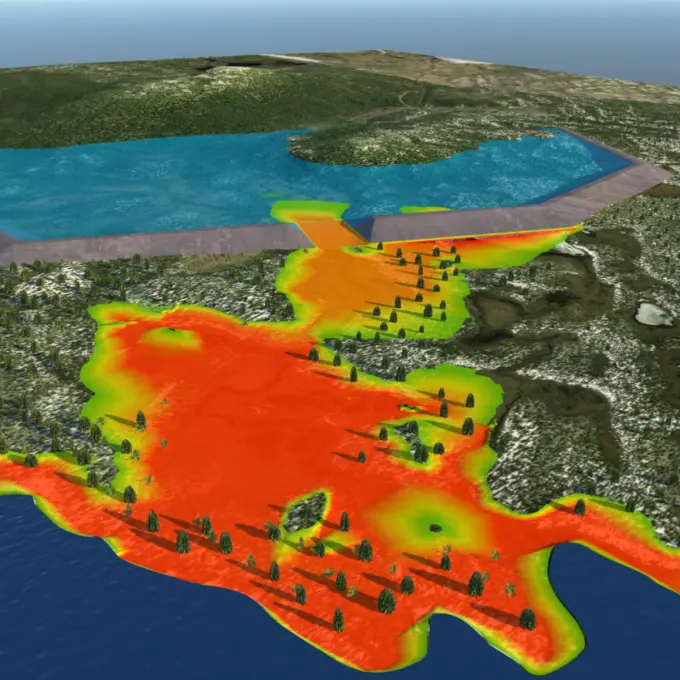

- Minimize the impact of tailings ponds on ecosystems

- Optimize your mine tailings management

- Respect regulations

-

-

Our approach

-

Your experienced partner, from studies to installation rehabilitation

Thanks to years of experience helping mining operators increase their operational performance, our experts can offer you effective management solutions for mine waste—tailings, waste rock, overburden—as well as sludge and contaminated water.

We plan, establish and implement each project in a safe and cost-effective manner based on high quality standards. We also provide support for mine rehabilitation, restoration, closure and monitoring.

-

-

Solutions we offer